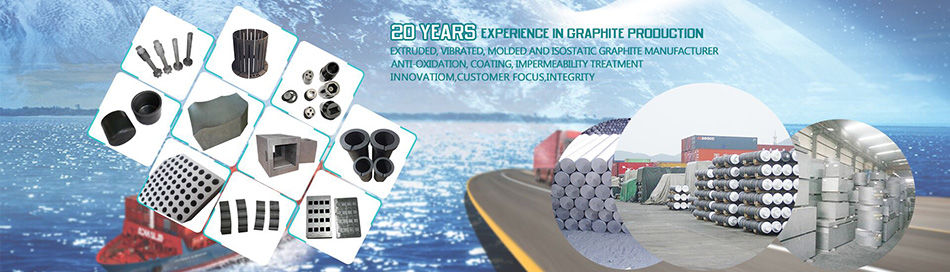

Graphite Crucible Application

This kind of graphite crucible is specially used for aluminum coated film production under vacuum condition.

Quality of graphite crucible will greatly affect film quality and production cost.

Vaccum evaporation aluminum coating is a process under vacuum condition to coat aluminum onto film substrates to form a composite film. Such substrates as BOPET、BONY、BOPP、PE、PVC, direct evaporation aluminum coating process is usually applied, while substrate as paper, leather, evaporation coating and transferring process usually applied.

The vacuum evaporation aluminum coating process requires high quality graphite crucible, and we are capable of stable and quality supplying.

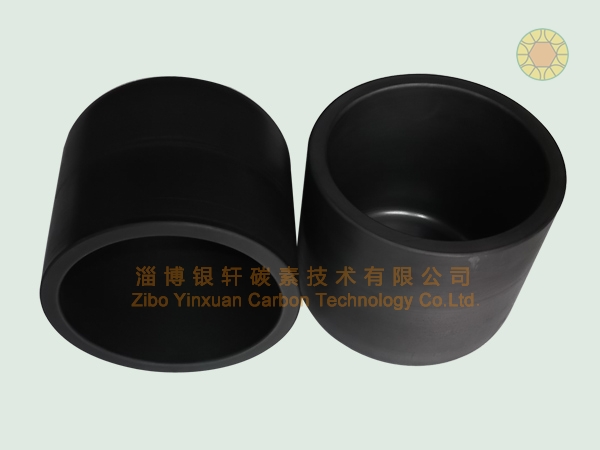

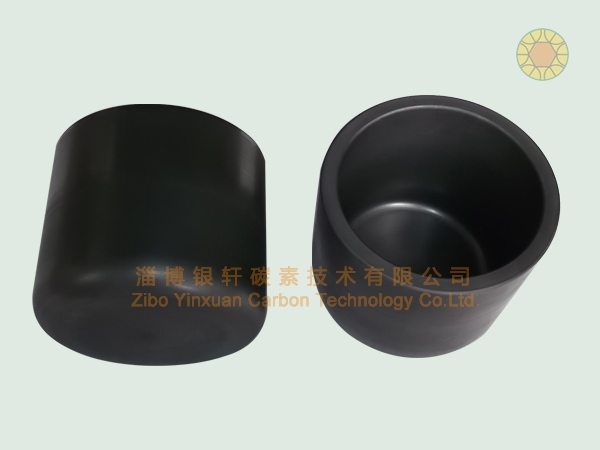

Yinxuan Graphite Crucible Advantages

►High quality raw material:

•Produced with special process. High bulk density and low porosity resist erosion of molten aluminum and its gas particles.

•High purity, low ash content graphite material prevents volatile substances, avoids spots, holes on aluminum coated film.

•Graphite crucible treated by special coating process, resists oxidation and maximizes service lifespan.

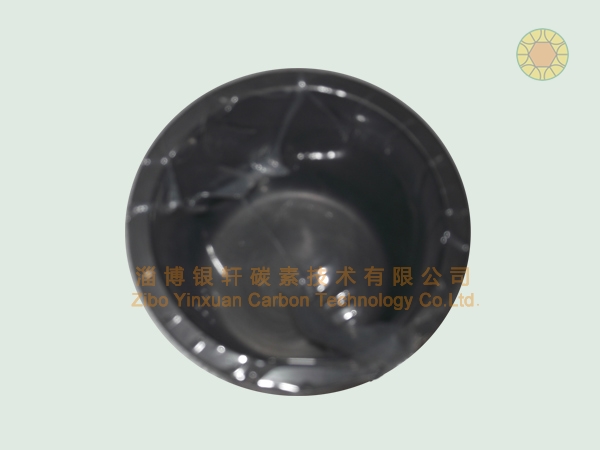

►Exact machining of graphite crucibles. Polished mirror surface and exact sizes.

Yinxuan graphite crucibles can be used continuously for 24~52 hours, or 22~48 cycles.

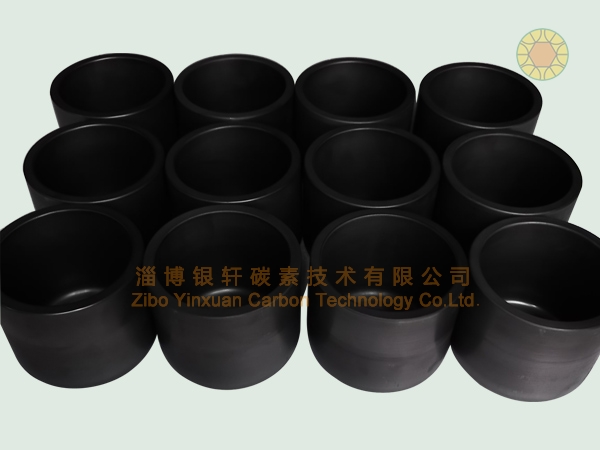

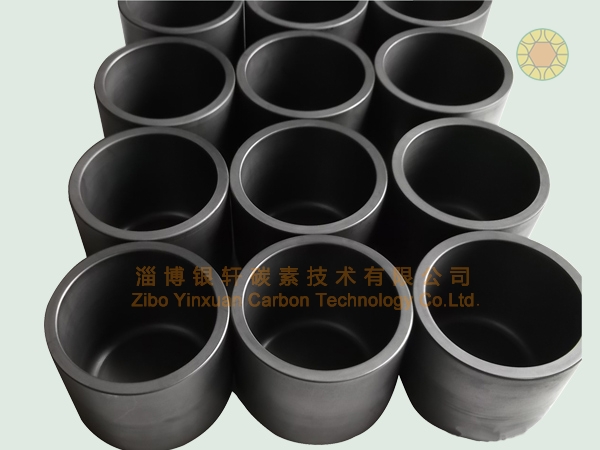

Graphite Crucible for Vacuum Evaporation Aluminum Coating

Graphite Crucible for Vacuum Evaporation Aluminum Coating

Graphite Crucible for Vacuum Evaporation Aluminum Coating

Graphite Crucible for Vacuum Evaporation Aluminum Coating

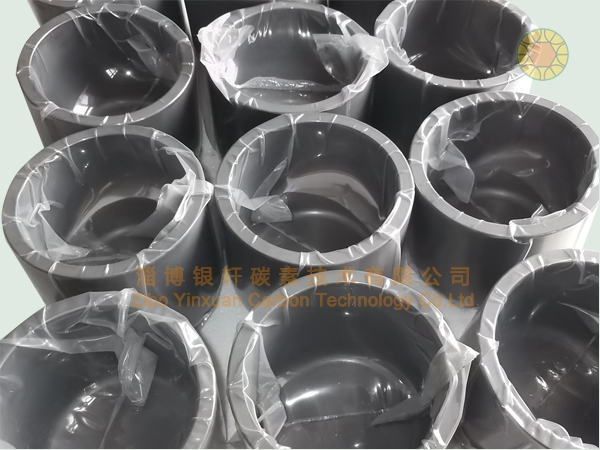

Inside Packing of Graphite Crucible

Inside Packing of Graphite Crucible

Packing of Graphite Crucible

Outside Packing of Graphite Crucible

Graphite Crucible in Use

|